To achieve different visual effects and feel, we can do embossing and debossing on tin boxes. The embossing / debossing technology in the industry refers to the uneven grain and pattern on the tin boxes that we can see in the market. It is a popular surface processing technology and its primary goal is to emphasize the important part of the design.

To do embossing / debossing, first of all, we must build molds. Then we use the molds to mold a decoration or design on the tinplate under the pressure so that the decoration or design is raised above or made under the surface of tinplate to achieve a three-dimensional effect. If the decoration or design is raised above the surface of tinplate, we call it “embossing”. If the decoration or design is made under the surface of tinplate, we call it “debossing”.

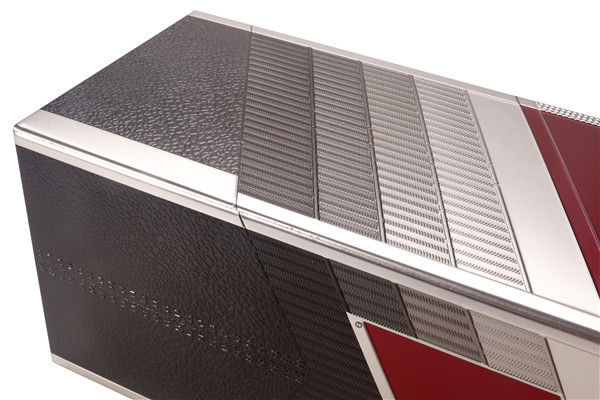

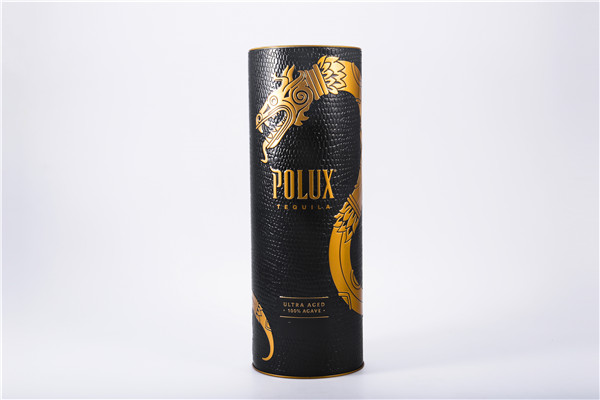

There is a special embossing / debossing. It is high-density and asking for high precision. We have well studied the nature of leather and achieved the leather effect on tin box by this high-density and high-precision embossing / debossing technology. High-density and high-precision embossing / debossing by precision machine tools is a breakthrough for tin packaging and it is developed by us.

Sense of depth can be achieved by the combination of fine printing and different fine embossing/ debossing, highlighting the uniqueness of the design. Leather-effect embossing/ debossing on tin box reproduces visual effect of leather and good touch of leather. The difficult part is the accuracy of the molds and the accurate alignment when making a tin box. A slight deviation will cause defectives.

We have applied the leather-effect embossing / debossing technology successfully on different products from different industries, for example, Chivas Regal wine tin can, Polux liquor tin can, Yihechun oral liquid tin box. We believe that the leather-effect embossing / debossing technology will be more and more popular in tin packaging for different industries.

Post time: Jun-03-2019